Lem Epoxy is often a kind of adhesive that may be recognized for its powerful bonding Attributes and versatility. It's really a two-portion adhesive, consisting of the resin and a hardener, which need to be mixed jointly in an effort to activate the bonding process. After blended, Lem Epoxy types a robust, durable bond that is certainly immune to heat, drinking water, and substances. This makes it a great option for a variety of applications, from house repairs to industrial jobs.

Lem Epoxy is accessible in a variety of formulations, which include rapidly-location and gradual-setting choices, and also diverse viscosities to go well with distinctive purposes. It can be used to bond a wide range of supplies, which includes steel, Wooden, plastic, glass, and ceramics. This can make it a flexible adhesive which might be useful for a wide array of initiatives, from restoring damaged house things to producing intricate crafts and jewelry. Lem Epoxy is additionally obtainable in different colors, rendering it uncomplicated to locate a formulation that matches the color from the materials being bonded.

Ways to Use Lem Epoxy

Working with Lem Epoxy is fairly simple, but it is necessary to follow the company's Recommendations very carefully to be able to reach the ideal final results. The initial step is to get ready the surfaces which will be bonded by cleansing them extensively to eliminate any Grime, grease, or other contaminants that could interfere Along with the bonding procedure. As soon as the surfaces are thoroughly clean and dry, another stage is To combine the resin and hardener together in the correct proportions. This will usually be accomplished by squeezing equivalent amounts of Just about every component onto a disposable floor, for instance a piece of cardboard, and afterwards mixing them along with a small stick or spatula.

Once the resin and hardener have already been carefully mixed, they need to be applied to the surfaces which have been to be bonded. It is necessary to operate immediately at this stage, as Lem Epoxy features a constrained Performing time before it begins to set. The adhesive needs to be utilized evenly to equally surfaces, and afterwards The 2 surfaces need to be pressed together firmly to make sure a great bond. It is vital to hold the surfaces in place until finally the adhesive has set, which may consider anywhere from a few minutes to several several hours, based on the formulation of Lem Epoxy being used.

Great things about Lem Epoxy

Lem Epoxy features many Added benefits that make it a popular option for bonding apps. One of several principal advantages of Lem Epoxy is its toughness and toughness. When cured, Lem Epoxy forms a bond that is immune to heat, h2o, and chemical compounds, making it suitable for use in a wide array of environments. This causes it to be a great option for programs where a solid, prolonged-lasting bond is necessary.

One more benefit of Lem Epoxy is its flexibility. It can be used to bond a variety of resources, such as metallic, wood, plastic, glass, and ceramics. This causes it to be a flexible adhesive which can be used for a variety of projects, from household repairs to industrial purposes. Also, Lem Epoxy is offered in various formulations to fit distinctive applications, together with rapid-placing and slow-setting solutions, together with diverse viscosities and colors.

Purposes of Lem Epoxy

Lem Epoxy has a variety of programs because of its toughness, toughness, and versatility. It can be employed for home repairs, including repairing damaged ceramics or restoring picket home furnishings. It's also typically Utilized in industrial options for bonding steel parts or developing composite products. On top of that, Lem Epoxy is popular within the crafting and jewelry-making industries because of its ability to bond a wide range of materials and its availability in different hues.

One common software of Lem Epoxy is from the automotive marketplace, the place it truly is utilized for bonding metal factors and fixing plastic elements. It's also commonly Employed in development for bonding concrete and masonry components. Additionally, Lem Epoxy is commonly Utilized in marine purposes on account of its resistance to water and substances. Total, Lem Epoxy has an array of purposes across various industries resulting from its power, longevity, and versatility.

Guidelines for Working with Lem Epoxy

When dealing with Lem Epoxy, there are various suggestions that will help ensure the finest outcomes. It is crucial to follow the maker's instructions meticulously in order to obtain the best bond power and toughness. This includes planning the surfaces thoroughly by cleaning them totally and mixing the resin and hardener in the proper proportions.

It is also vital that you get the job done quickly when making use of Lem Epoxy, as it's a minimal Doing the job time before it begins to set. Which means it is crucial to obtain all the mandatory applications and materials ready just before mixing the adhesive. Furthermore, it is necessary to apply the adhesive evenly to equally surfaces and press them with each other firmly to make certain an excellent bond.

Security Precautions when Using Lem Epoxy

While Lem Epoxy is a flexible and productive adhesive, it is crucial to acquire suitable security precautions when applying it. This incorporates donning gloves and eye safety when handling the adhesive to be able to safeguard the skin and eyes from connection with the resin and hardener. It's also essential to operate within a properly-ventilated region when working with Lem Epoxy as a way to avoid inhaling any fumes Which may be provided off during the curing approach.

Comparing Lem Epoxy with Other Adhesives

When comparing Lem Epoxy with other adhesives, there are many components to look at. One of several main advantages of Lem Epoxy is its toughness and durability. After cured, it sorts a bond which is immune to warmth, water, and chemical compounds, rendering it ideal for use in a wide array of environments. On top of that, Lem Epoxy is obtainable in several formulations to accommodate various programs, which include fast-setting and slow-environment selections, as well as various viscosities and colors.

Michael Fishman Then & Now!

Michael Fishman Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Tyra Banks Then & Now!

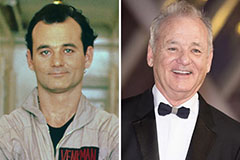

Tyra Banks Then & Now! Bill Murray Then & Now!

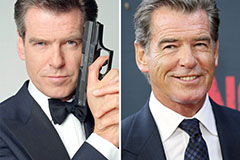

Bill Murray Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!